Airlaid mesh belt

The best domestic monofilament raw materials are used for warp and weft wire. The wire and weaving structure of the three kinds of wefts make the HY408S high-speed equipment operate with a particularly good balance between the peeling performance and the adhesion performance.it is the first generation product specially used for high-speed thin fabric production.

Product parameters

| Airlaid mesh belt | |

| Suitable for lines | Airlaid Nonwoven Equipment |

| Wrap density | 16pcs/cm |

| Weft density | 12pcs/cm |

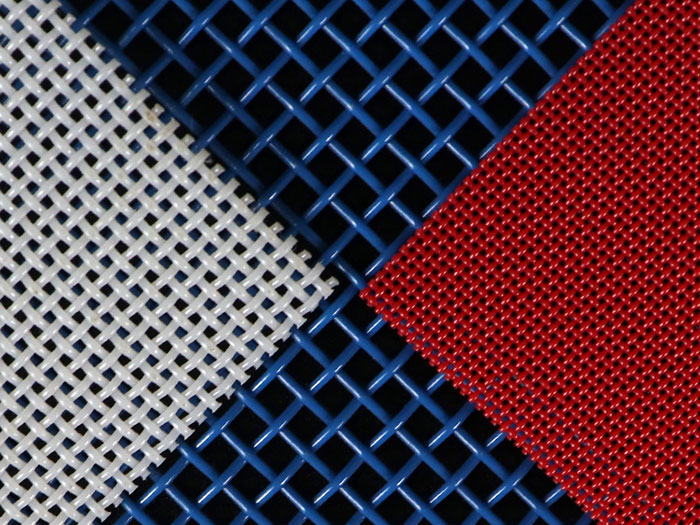

| Wrap diameter | 0.50mm red |

| Weft diameter | 0.80mm red 0.30mm black and blue |

| Reticulate | 1.5layers |

| Thickness | 1.85mm |

| Breaking strength | ≥2000N/cm |

| Joints | OEM |

| Air permeability(127pa 20cm² under conditions) | 590±30 CFM |

| Suitable for line speed | Designed line speed:within 600m/min,Customer usage value:580m/min |

Product advantages

We supply various airlaid mesh belts,adopt 100% new good raw materials. Besides, our advanced weave equipment make sure the belt structure stable and grid even,our professional workers make sure the connector smooth and stable.If you have special request about specifications, we can also OEM for you.So if you produce airlaid nonwoven fabric and need mesh belts, just feel free to contact us, we will give you best solution and price.

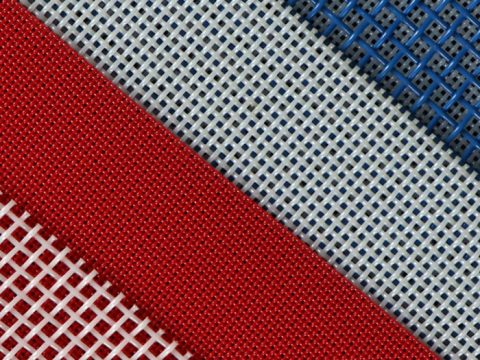

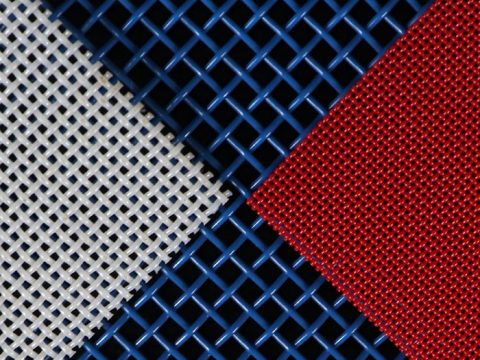

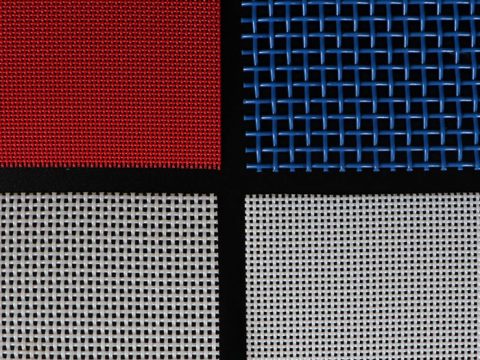

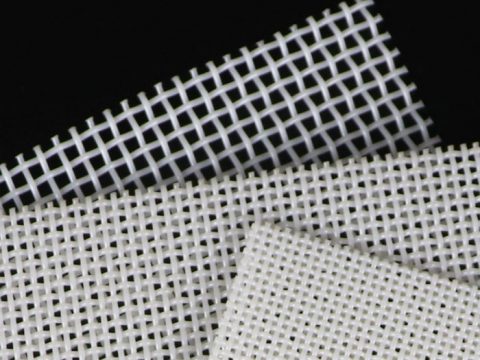

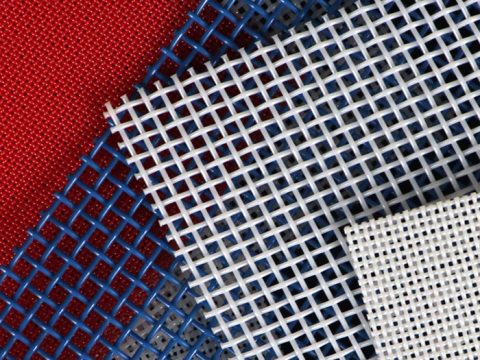

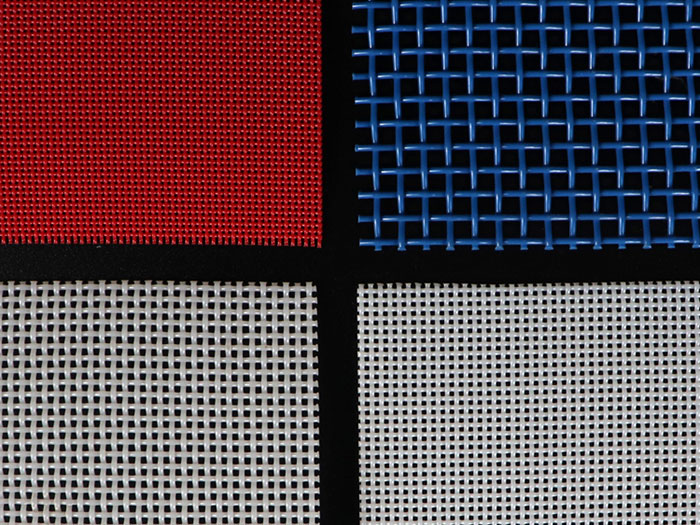

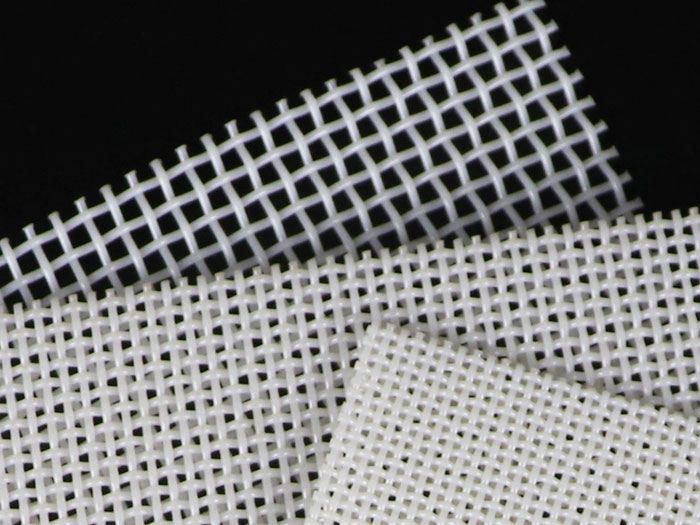

Product display

Product Features

- 01High precision weaving technology,to keep air permeability same,and the nonwoven fabric uniform.

- 02Smooth belt structure to ensure low weight fabric peel off easily.

- 03Fluorinated surface treatment, to make the fiber pulp block easy to clean.

- 04Advanced aerodynamic design,to make it convenient and quick for wind pressure control.

- 05Oblique line chamfering pattern,softer net formation and convenient pressure control.

- 06Seam joint structure lock tightly,no jumper wire.

Product application

For thin fabric, high speed non-woven equipment.